Harnessing AI to Transform Broker Relationships and Elevate Client Satisfaction

Peerless Products manufactures high-performance aluminum architectural-grade windows and doors. The brand is well-known nationally and its products are sought after for residential and commercial applications. Peerless’ safety and workers’ compensation programs were in transition. The environmental manager, Haley Perez, who had previously not been very involved in safety, was promoted when the head of safety left the company. Additionally, the company changed carriers, bringing new expertise from The Hartford to bear. In her new role, Haley Perez, took ownership of the safety program and took the initiative to explore the CompScience offering presented by The Hartford.

Start of Engagement

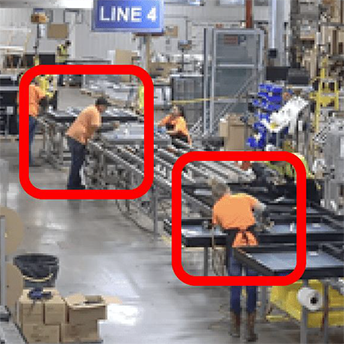

To kick off the risk reduction program, Peerless shared workplace video, which CompScience requires to leverage the full power of its Intelligent Safety Platform. To quantify risks in operations, CompScience applied over 50 AI “detectors” to analyze specific risks in the operations. Data science techniques were then applied and specific risk events were identified by work area, time of day, and type of potential injury.

Results Metrics

In Haley’s words, “CompScience can put things in perspective.” The client saw improvements across three leading indicators of injury and accidents in just four weeks. Peerless uploaded a second set of workplace video files, and CompScience ran the data through the Intelligent Safety Platform. The second risk report clearly indicated that training and workflow improvements led to a dramatic overall reduction in risk exposures.

73%

Reduction in line of sight hazards

50%

Reduction in lost time and DART rates

Increased Productivity

With fewer injuries, the facilities were able to maintain higher productivity levels without the disruptions caused by workplace accidents.

Lower Employee Turnover

The enhanced focus on safety contributed to higher employee satisfaction and retention, as workers felt more valued and protected.

Reduction in Lost Hours Due to Injuries

The decrease in the number of injuries directly translated into fewer lost work hours, contributing to more consistent operations and higher-quality output.