What are workplace safety analytics and how do the systems work?

Workplace safety is a crucial concern for businesses across all industries, and many organizations are investing in safety programs and technologies to prevent accidents and injuries. Workplace safety analytics is a key tool that businesses can use to gain insights into their safety programs and identify areas for improvement. Contact CompScience to learn how the Intelligent Safety Platform can help your organization with workplace safety analytics.

Workplace safety analytics involves collecting and analyzing data related to workplace safety, such as injury rates, incident reports, and safety training records. By applying data science techniques to this data, businesses can gain valuable insights into their safety programs, identify potential hazards, and take proactive steps to prevent accidents and injuries.

Data science is a field that involves using statistical and computational methods to analyze data and extract insights from it. In the context of workplace safety analytics, data science can be used to analyze a wide range of safety-related data, including:

- Injury and illness data: Businesses can collect data on the number and type of workplace injuries and illnesses that occur, as well as information on the severity of these incidents. By analyzing this data, businesses can identify trends and patterns in injury rates and target interventions to prevent common types of injuries.

- Incident reports: Businesses can collect data on the types of incidents that occur in the workplace, as well as information on the root causes of these incidents. By analyzing this data, businesses can identify areas where their safety programs may be falling short and take corrective action.

- Safety training records: Businesses can collect data on the types of safety training that workers receive, as well as information on how frequently this training is provided. By analyzing this data, businesses can identify gaps in their safety training programs and take steps to ensure that workers are adequately trained to perform their jobs safely.

In addition to these types of data, businesses can also collect data from a variety of other sources, such as equipment sensors, worker wearables, and safety audits. By analyzing this data in combination with other safety-related data, businesses can gain a more complete picture of their safety programs and identify potential hazards and areas for improvement.

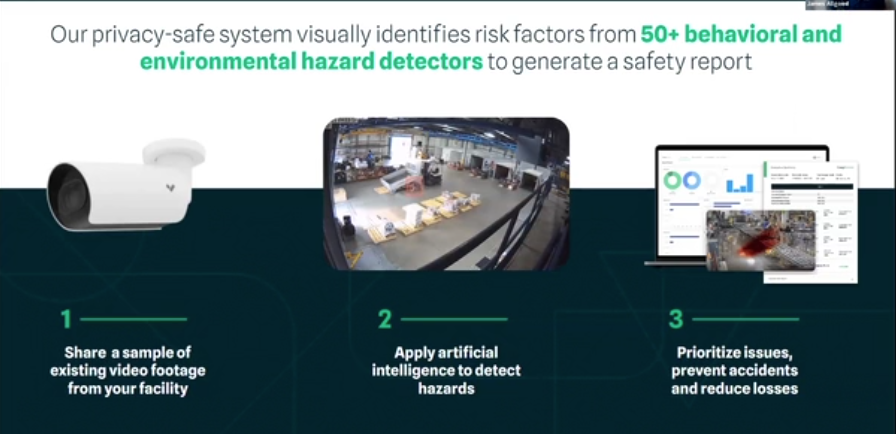

One example of a business using data science to improve workplace safety is a large warehouse operator. The warehouse company uses a wide range of sensors and cameras in their warehouses to collect data on worker movements and equipment usage. This data is then analyzed using machine learning algorithms to identify potential hazards, such as workers walking into each other or equipment being operated unsafely. By analyzing this data in real-time, the warehouser can take proactive steps to prevent accidents and injuries from occurring.

Another example of a business using data science to improve workplace safety is a large manufacturer of heavy equipment. This manufacturer uses data from equipment sensors to identify potential hazards and proactively address maintenance issues that could lead to accidents. By analyzing this data, the manufacturer can also identify patterns and trends in equipment usage that could lead to injuries and take steps to address these issues.

While workplace safety analytics can provide valuable insights into safety programs and help prevent accidents and injuries, it is important to note that there are potential challenges and limitations to this approach. One major challenge is the need for accurate and reliable data, as inaccurate or incomplete data can lead to incorrect conclusions and ineffective interventions. Additionally, there may be concerns around privacy and worker surveillance, as businesses collect and analyze more data related to worker behavior.

To address these challenges and ensure that workplace safety analytics is used effectively, it is important to involve workers in the development and implementation of these programs. This can involve providing workers with training and education on how data science works, as well as soliciting feedback and input from workers on how to improve these programs. Additionally, businesses can work with data scientists and safety experts to ensure that their analytics programs are designed to address the unique needs and challenges of their specific industry and workplace.

Workplace safety analytics systems are designed to identify potential risks and hazards in the workplace, and to help organizations take proactive measures to prevent accidents and injuries. These systems use data analytics and machine learning algorithms to analyze data from various sources, such as accident reports, incident logs, safety inspections, and employee feedback.

Here are the key steps in how workplace safety analytics systems typically work:

- Data Collection: Workplace safety analytics systems collect data from various sources, such as accident reports, incident logs, safety inspections, and employee feedback. The data is usually collected in a centralized database.

- Data Cleaning and Preprocessing: The collected data is cleaned and preprocessed to ensure that it is accurate, complete, and consistent. Data cleaning involves identifying and correcting errors, such as missing values or outliers, while data preprocessing involves transforming the data into a format suitable for analysis.

- Data Analysis: The cleaned and preprocessed data is analyzed using statistical and machine learning algorithms to identify patterns, trends, and anomalies that may indicate potential risks and hazards in the workplace.

- Risk Assessment: The results of the data analysis are used to assess the level of risk associated with different activities, tasks, and areas in the workplace. This helps organizations prioritize their safety efforts and allocate resources more effectively.

- Risk Mitigation: Based on the risk assessment, organizations can take proactive measures to mitigate potential risks and hazards in the workplace. This may involve implementing new safety procedures, providing additional training to employees, or modifying equipment or work processes.

- Monitoring and Evaluation: Workplace safety analytics systems monitor the effectiveness of the risk mitigation measures implemented by the organization. This allows organizations to track progress, identify areas for improvement, and adjust their safety strategies as needed.

Overall, workplace safety analytics systems are powerful tools for organizations looking to improve workplace safety and prevent accidents and injuries. By analyzing data from various sources, these systems can help organizations identify potential risks and hazards, prioritize their safety efforts, and take proactive measures to mitigate these risks.

In conclusion, workplace safety analytics is a powerful tool that businesses can use to gain insights into their safety programs, identify potential hazards, and take proactive action.

Here’s the definition of safety analytics. Here’s how to calculate your safety analytics roi.