Ergonomics, Featured, Workers' Comp, Workplace Safety

Winter Workplace Hazards: Tips for Hazardous Industries

Winter brings unique challenges to workplaces, especially in industries where medium to high hazards are already part of the environment. Icy conditions, heavier gear, and changes in workflow all contribute to increased risks. Addressing slip/trip/fall incidents, ergonomic challenges, and powered machinery hazards is critical to keeping workers safe and preventing costly workers’ comp claims. Here are practical tips to tackle these winter hazards head-on.

Preventing Slips, Trips, and Falls

Icy surfaces, wet floors, and poor lighting during winter create the perfect storm for slip-and-fall accidents. Here’s how to mitigate these risks:

- De-icing Protocols: Regularly salt and sand walkways, loading docks, and high-traffic areas. Ensure that outdoor stairways and ramps are clear of snow and ice.

- Floor Maintenance: Use absorbent mats and wet-floor signage indoors to manage melted snow and water brought in on workers’ boots.

- Proper Footwear: Equip workers with non-slip, insulated footwear designed for icy conditions.

- Lighting: Winter’s shorter days make it crucial to ensure outdoor and indoor lighting is adequate, especially in walkways and parking areas.

Ergonomics in Cold Weather

Cold conditions often require workers to wear heavier clothing, which can limit movement and add strain to physical tasks. Overexertion and repetitive motion injuries become more likely.

- Layer Strategically: Encourage workers to wear lightweight, moisture-wicking layers that allow flexibility. Avoid overly bulky outerwear that restricts movement.

- Adjust Material Handling Techniques: Train workers to adapt lifting practices when wearing gloves or handling cold, slippery objects. Ensure materials are ergonomically positioned to minimize bending, reaching, and twisting. Implement carts to reduce or eliminate carrying events.

- Breaks and Warm-Up: Promote regular breaks in warm areas to reduce muscle stiffness and the risk of sprains or strains.

- Tool Ergonomics: Provide tools with ergonomic grips that are easy to handle with gloves.

Powered Machinery in Winter

Machinery operations in cold weather pose unique challenges, from reduced visibility to mechanical failures caused by freezing conditions.

- Inspect Before Use: Perform daily checks to ensure machinery, forklifts, and other powered equipment are functioning correctly and free from ice, grit/salt, or condensation.

- Surface Safety: Ensure that equipment operates on dry, stable surfaces to prevent sliding or tipping.

- Operator Visibility: Install heated mirrors and windshields to prevent fogging, and equip machinery with bright, flashing lights to improve visibility during darker winter days. Closed cabs with limited airflow will fog up faster.

- Training for Seasonal Hazards: Train operators on the additional risks of winter, such as reduced traction and longer stopping distances for forklifts and other vehicles.

Winter Safety Is a Team Effort

At CompScience, we know that prevention is key. By addressing these hazards and equipping workers with the right tools, training, and environment, you can reduce risks and avoid costly claims. A proactive approach to workplace safety ensures productivity continues—even when winter conditions pose extra challenges.

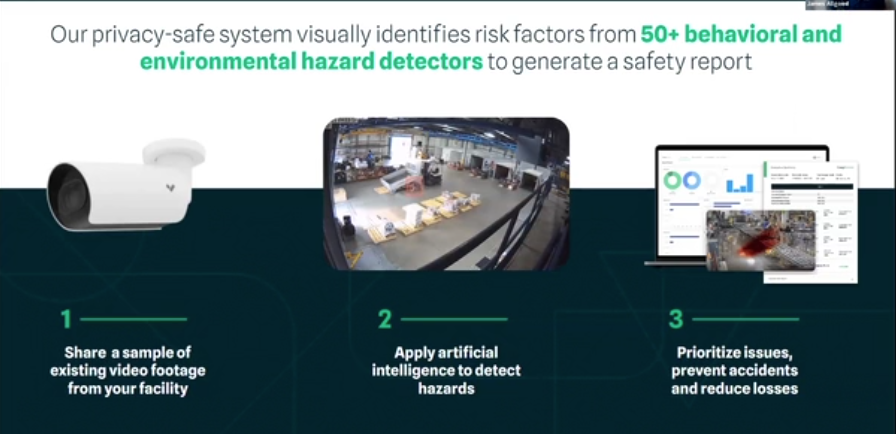

Looking for more ways to safeguard your workplace? Explore CompScience’s AI-powered workers’ comp insurance or safety analytics for actionable insights that reduce risks and transform your workers’ comp strategy.